Our Product

Showing 25–36 of 90 results

Cup Brushes, Crimped Wire

Cup Brushes, Crimped Wire

Cup Brushes, Knot Wire

Cup Brushes, Knot Wire

Cut & Polish Wheel

PRODUCT DETAILS:

With strong grinding capability, cut & polish wheels can take the place of traditional cotton grinding wheels without any scratch left in the workpiece. Excellent for removing residues from casting parts and making nice surface finishing. The wheels can be used for either manual or automatic operation.

Deburring Wheel

PRODUCT DETAILS:

It is specially designed to remove burr and polish at a time. No secondary burr, Make fine lines on work piece exterior and improve the smooth finishing on surface. Cleaning and removing rust, corrosion, weld discoloration and scratches. Used for hand tool, surgical instrument, gear, cutlery and metal fabrication surface treatment.

Decorative Finishing Wheel

PRODUCT DETAILS:

Specially designed for drawing processing on the metal plating parts, clear lines, good effect and no adhesive & black lines remains on the work piece. Used for copper-plating, nickel work piece drawing line, cutter blade drawing, brushed aluminum products polished before painting. Like the handle, lock, antique copper, building hardware, frame and various wood products, marble etc.

Double Rows Cup Brushes

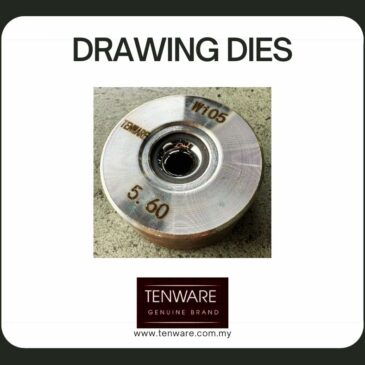

Drawing Dies

Tungsten Carbide Drawing Dies

Tungsten Carbide Drawing Dies (TC Dies) are widely used in the wire industry, particularly for steel wire drawing applications. Wire drawing is a metalworking process in which the cross-section of a wire is reduced by pulling it through a single die or a series of drawing dies to achieve precise and consistent diameters.

These dies consist of a high-quality tungsten carbide inner nib, securely mounted within a high-strength steel casing, providing excellent wear resistance, dimensional stability and long service life under continuous, high-speed drawing conditions.

We offer tungsten carbide drawing dies in a wide range of nib and bore sizes, with custom specifications available to meet individual customer requirements across various wire drawing applications.

Key Benefits

-

Wide range of sizes available

-

Excellent hardness and abrasion resistance

-

Cost-effective for a variety of wire processing applications

-

High thermal conductivity for efficient heat dissipation

-

Long service life with consistent drawing performance